当环境必须保持绝对低的振动或施工噪声时,许多亚洲客户首选静压植桩机,尤其是使用了低噪音的液压动力站。而在欧洲,当周边环境不能受打桩影响时,则会采用使用了先进技术的免共振振动锤。

静压植桩机需要克服土壤的摩擦,需要使用更多的力量驱动桩,使用蛮力以达到设计深度。植桩机最适合粘土,桩路径上的石头和卵石会被压实。静压植桩机是自驱动的,它利用内部机构沿着施工的桩墙进行移动。这个过程需要充足的现场组织,重新定位设备需要耗费很多的时间。打桩的速度是固定的,不受土壤条件的影响。施工方需要进行专业培训,操作设备处理类似转弯的复杂动作。

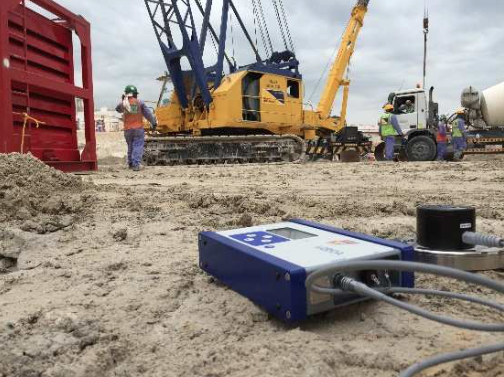

无共振振动锤使用不同的机制:锤的振幅使土壤液化,改变其摩擦力,推进钢板桩的施工。振动的钢板桩将运动轨迹中的的石头推到一边,扫清施工道路。 振动锤可安装在履带吊机或挖掘机臂上。它们可在施工现场快速移动,不用做更多的事前规划。该设备尺寸紧凑,允许锤在密闭空间工作。振动锤的驱动速度取决于土壤条件,易操作性可比静压的方法强得多。

什么是免共振技术?

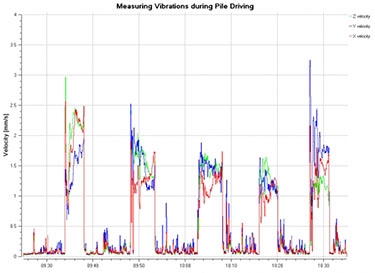

传统的振动锤具有恒定的偏心力矩。在启动和停止时,当接近周边建筑的临界频率范围时,恒定振幅会导致起重机的吊杆和土壤产生令人不安的负面振动。它不只是在工作区,还可延伸到周边相当长的距离。当工作在高度城市化的地区或附近有脆弱的建筑结构时,这可能会对附近的结构造成损坏。在施工这些应用时,普通频率振动锤不是一个可行的选择,承包商将需要选择一个高频振动锤。

ICE高频(可变力矩)振动锤,其频率每分钟可从0到2300转调节。关键在启动和停止时,它不会产生任何振动。通过临界频率区域后,偏心重量自动调整,并同步到当前的偏心力矩。

使用ICE 免共振技术来施工的好处是:成本低、施工灵活,可安装于轻量级挖掘机或悬挂在起重机上。它可将对周围环境的干扰降到最低,是在狭窄工作条件下的理想选择。