Research shows limited soil settling effect of sheet pile retaining walls.

In China thousands of projects are carried out each year. Sheet piles are a great fit for the modern reduce -reuse -recycle practices for temporary foundation works. Here are at the Deep Foundations WeChat Group we discuss this topic regularly. This week we are sharing exciting results from scientific research on soil settlement caused by the driving and extraction of sheet piles.

The primary use of sheet piles is to create a temporary or permanent barrier between excavations and their surroundings, examples are quay walls, soil retaining walls, tunnels, and subterranean parking garages. Sheet piles are also well suited for temporary excavation work such as a retention wall for a excavation pit. In China diaphragm walls are the preferred method for building retaining walls. In contrast to a diaphragm wall the sheet pile wall is a temporary structure. This type of temporary solution fits well with modern trends, such as the reduction of concrete bentonite and steel reinforcement cages. In practice, the materials used in the diaphragm walls often have no additional structural function other than retaining soil and will be hard to remove after completion of construction work. Sheet piles, however, can easily be extracted and reused on a new site. Today we make the case again for the benefits of using sheet piles for excavations up to 18 meters, by addressing some common misconceptions about settlement of soil during the installation and extraction of sheet piles.

A general trend in society is that environmental concerns are gaining importance (such as bentonite pollution) and acceptance of discomfort such as noise emissions and traffic jams is declining. Therefore there is a growing need to study the environmental aspects and potential risks of building activities especially in urbanized areas.” Construction projects now require an assessment of all possible environmental effects to secure approval. Sheet pile walls and resonance free vibratory hammers address these critical issues. Over the years much attention has been given to the avoidance of vibration disturbances. With the advance of resonance free piling methods and the general acceptance of this method attention has shifted to the subject of soil settlement during vibratory sheet piling. The prediction of soil settlement remains a challenging job. Dr. P. Meijers focused his PhD research on refining the modeling of soil settlement during installation and extraction of temporary sheet pile walls. Much of the information below is a paraphrasing of his thesis titled: ”Settlement During Vibratory Sheet Piling University of Delft Department of Civil Engineering and Geosciences 2007”. The link to the full paper is provided at the end of this article.

In his thesis Dr. Meijers reviews existing prediction models and develops his own. His model is then verified with field work. The field work showed that the modeling work still needs improvement but the data from the field work is extensive and can serve to make informed design decisions.

The most likely mechanisms that are responsible for soil settlement during pile driving are the densification of the soil and the displacement of a soil due to the volume of the sheet pile. Both are discussed in more detail below.

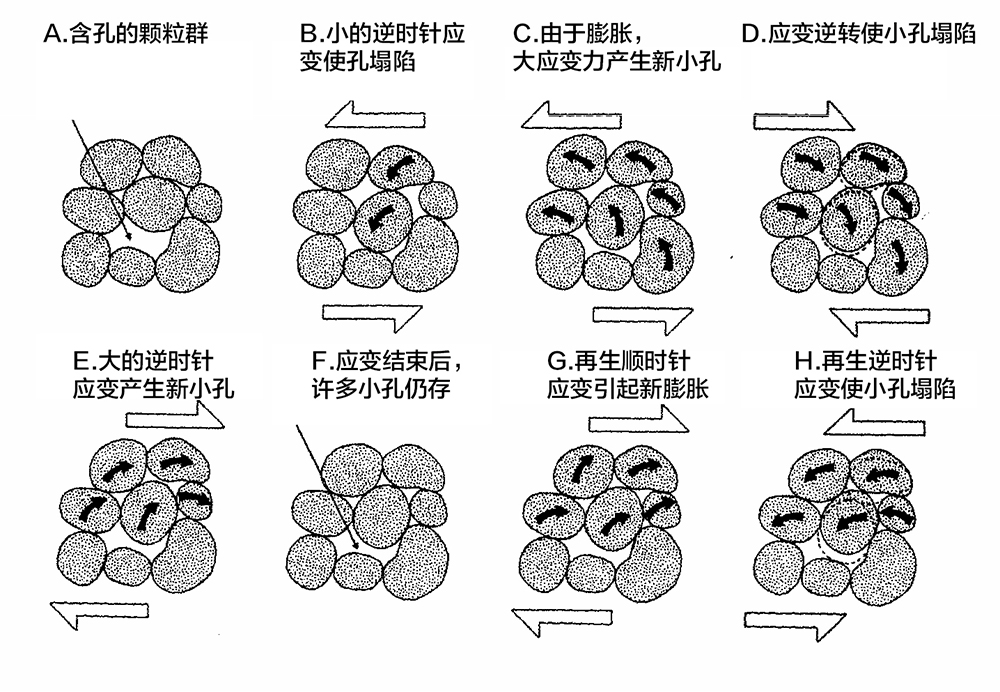

Most of the soil densification occurs during installation of the sheet pile wall. At the interface of the sheet pile and soil, vibrations are transferred to the soil. Vibration waves travel into the soil, the amplitude of the waves decreases with distance. The soil is loaded cyclically due to these vibrations. It is this loading that is responsible for the densification and the excess pore pressures in the soil. Cyclic loading is a continuous process and the load changes continually in response to soil conditions and driving force, resulting in continuous changes in the soil matrix. Soil grains that are first tightly constrained may lose their confining stress and tumble in voids within the soil matrix. Other grains rotate a little, while others may start to slide over each other. The result is that the soil matrix changes a little attains a new fabric and possibly also a new density. As the pile descends, more and more grains will obtain a stable situation and thus the tendency for deformation will reduce. In practice the amount of soil settlement is limited as the inserted volume of the sheet pile counteracts the effect of densification.

During sheet pile extraction

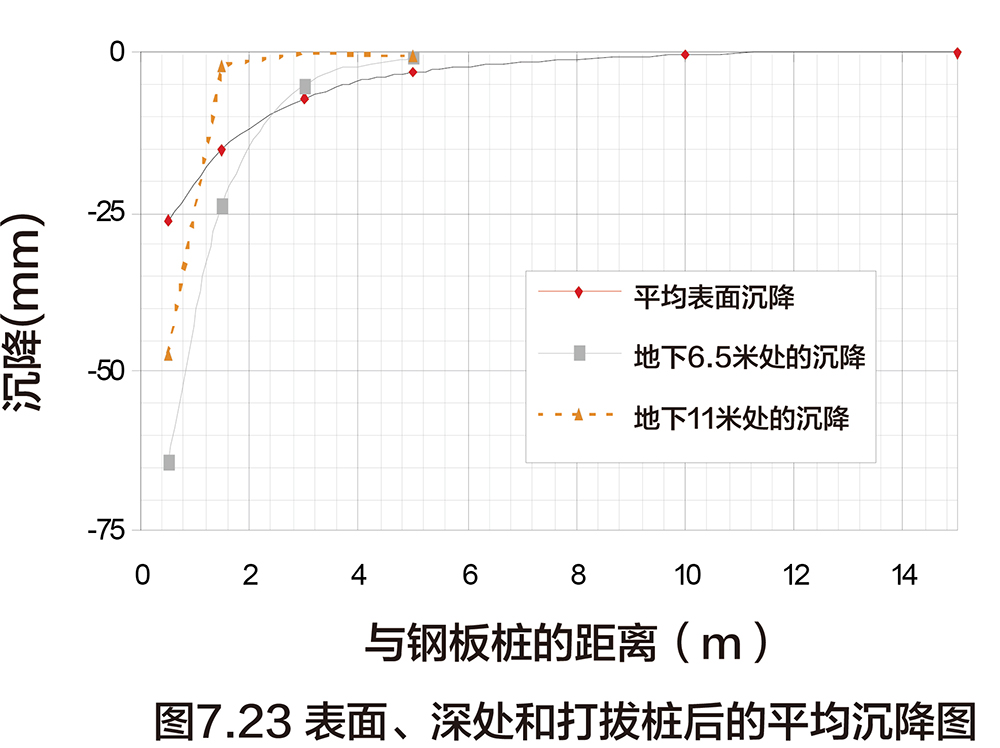

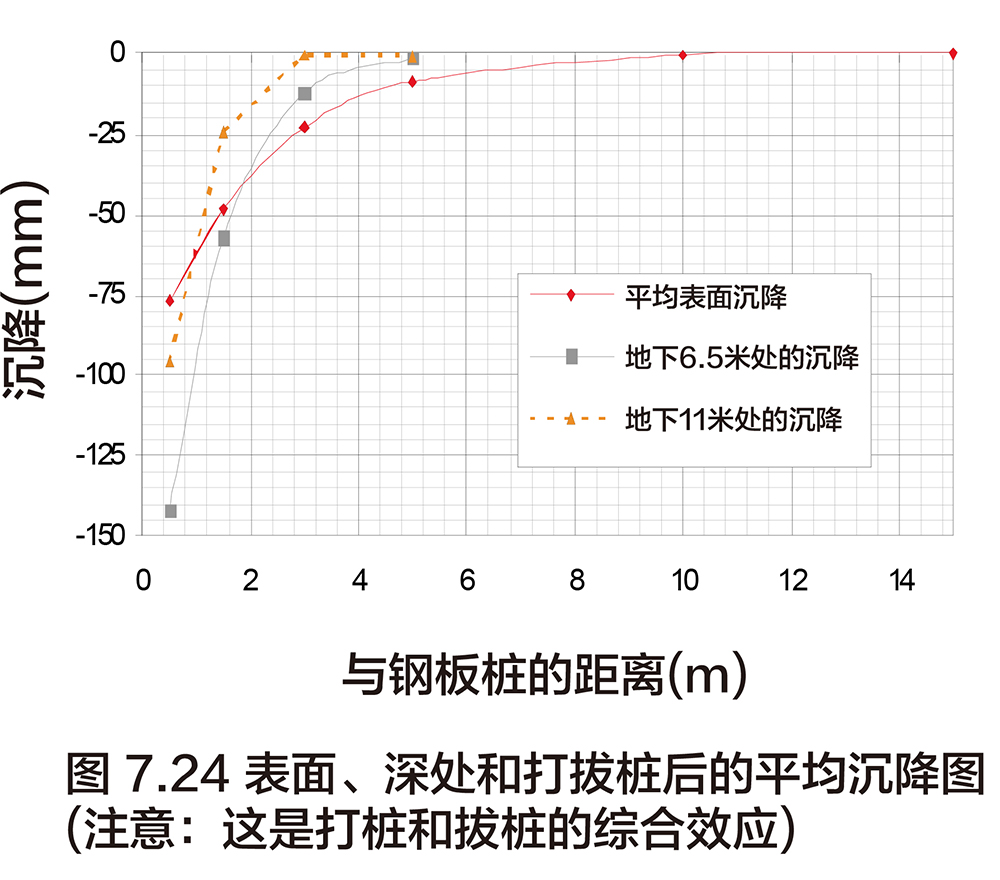

During removal the process is identical. The vibratory hammer vibrates in place until the pile comes loose. “At this stage all kind of things may happen in the soil, such as the generation of excess pore pressure around the sheet pile, stretching of the sheet pile, and decrease of the interface friction between sheet pile and soil. When the degradation (including liquefaction) has reduced the friction between sheet pile and soil sufficiently the sheet pile starts to move. After this stage, the sheet pile is pulled out of the soil mostly at an increasing speed.” The sheet pile represents a volume and removing of the sheet pile will thus leave some space in the subsoil. “The removed volume will be in excess of the net steel volume when soil sticks to the sheet pile. In sand this effect is small (in the order of 1 mm or less) but in clay large lumps may stick to the sheet pile. This void will not remain intact. Sand will flow to this void to fill it. This will result in additional settlements.” To reduce the volume of clay that sticks to the pile during extraction it is common practice to coat the pile with a lubricant, or to first drive the sheet pile down a little further in order to decrease the friction at the sheet pile-soil interface which then prevents lumps of clay sticking to the sheet pile. Meijers concludes that “For the phase removal of the sheet piles, the measured surface settlement is in good agreement or a little below the calculated values of the existing models. For this situation the settlement during removal is dominated by the removal of the volume of the sheet pile. The general trend is that close to the sheet pile the actual settlement is reasonable, while at larger distances the actual settlement is less.”

Dr. Meijers’ research shows that in sandy soil conditions, when using high frequency vibratory hammers, settlements due to vibratory installation of sheet piles vary between zero and nearly 1-meter distance of the sheet pile wall. The settlement depth range is usually within the range of a few centimeters. In most cases the reported settlements are based on visual observations and not on methodically collected data. In many cases the settlements due to sheet piling remain unnoticed, as they are exceeded by other disturbances at the working area (such as from heavy equipment movements). “For about 50% of the sheet piling projects studied the settlement close (>1 meter) to the sheet pile wall exceeds 10 cm. At a distance equivalent to about half the driving depth of the pile the surface settlements become negligible.”

These observations of soil settlement are in line with surface settlements associated with the working of the grab at the start of excavation work for diaphragm walls.

Foundations Industry developments

The foundation industry is seeing rapid changes, sheet piles offerings are changing to include wider and longer piles combination walls, with sheet pile-casing or sheet pile- king pile are becoming available, piling equipment is making strides, regulators are pushing for more environmentally friendly methods, and design institutes are on board to bring real change to the market. More research needs to be carried out for different soil types and ICE is seeking cooperation partners to further the industry. Please get in touch with your proposal!

Sources:

Settlement during vibratory sheet piling, Dr. P Meijers.

https://repository.tudelft.nl/islandora/object/uuid:1be3ad18-4f31-4003-a3ad-444d87771900/datastream/OBJ/download